What is a Flexible Shaft Coupling?

Flexible Shaft couplings are mechanical devices that connects two rotating shafts, transmitting power from the driver to the driven equipment, while accommodating various types of misalignment—be it angular, parallel, or axial.

Misalignment may occurs when both shafts are not aligned, which can lead to excessive force on either size of the driver or driven load, causes problems such as vibration-related fatigue or breakdown of parts for the equipment.

Common misalignment are angular misalignment and parallel misalignment and how Flexible Shaft Coupling helps to prevent these misalignments?

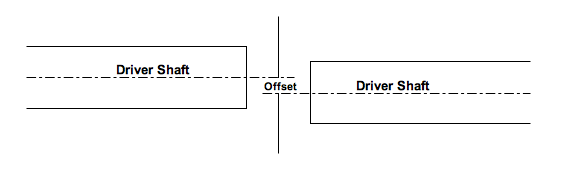

Parallel Misalignment

Parallel misalignment occurs when either the horizontal or vertical plane have centrelines parallel to each other, but are offsets.

Alignment is only achieve when the position of the rotational center is aligned in a straight line, both horizontally and vertically.

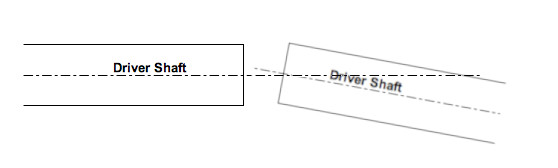

Angular Misalignment

Angular misalignment occurs when the shaft ends of both the driver and driven is at an angle.

What casues misalignment?

Even when the alignment of the shaft were perfectly aligned during installation, misalignment can still occurs due to continuous operations of the equipment. Here are the causes of shaft misalignment:

- Wear and Tear of driver or driven equipment.

- Thermal expansion of different material expand at different rates causes equipment to move proportional to another.

- Equipment that has high starting torque will cause backlash over time.

- Driver and Driven equipment not on same base.

- Soft base foundation may "sink", caused by the weight of the equipment.

Types of Flexible Coupling

- Gear Couplings: These flexible couplings handle high torque transmission between non-collinear shafts. They find use in large industrial machinery requiring substantial power.

- Tyre Couplings: Made with neoprene rubber with polyester cord, the 2 hubs is connected by a tyre which can accommodate high degree of misalignment, absorbing vibration that may be caused by the driven equipment.

- Jaw Couplings: Made from flexible materials, jaw couplings accommodate misalignment caused by thermal expansion or manufacturing inefficiencies. They are commonly found in lower-power transmission systems, such as electric motors and internal combustion engines.

Flexible couplings in general are more adaptable to misalignment and are used in many applications because they can protect against angular misalignment and offset. Flexible couplings withstand complex loads from vibration, impact, parallel misalignment as well as angular misalignment.

These couplings can be manufactured using different materials such as stainless steel, zinc alloy, aluminum for the hubs and rubber, elastomer insert or element to increase protection against vibration by increasing the damping properties.

Depending on the requirement of the drive, a type of coupling can have certain advantages over another and vice visa.

Example: A Tyre Coupling may have the most tolerance against angular & parallel misalignment and vibration, however due to the properties of the "Tyre", the designed coupling maybe be larger in size compare to a Jaw coupling, where space constraint sometimes can be a point of consideration in the selection.